Get all of the promised power from the laser. Choose LithoWise. One fiber and done

LASER AND FIBER DISCUSSION

Did you ever wonder why you blow fibers? Why you are spending money to buy a second or third fiber? Why you are spending valuable OR time replacing fibers just to complete the procedure? Why it sometimes takes so long to crack a stone? The short answer is, the full beam power capacity delivered to the fiber is not passing through the transmissive core of the fiber thread. The beam may never fully enter the fiber, partially enter, or is lost when the scope bends. Because of the decrease in expected power it takes longer to crack a stone, often, long enough that the fiber fails before the stone is cracked. Sometimes the scope gets damaged too.

There are two irrefutable facts to consider when manufacturing a Laser Fiber.

The first irrefutable fact is that a specifically designed fiber optic thread is the key to a great fiber device. The LithoWise fiber utilizes our own design and directs the power, all of it, to the target. This includes the errant power of an out of spec laser. Imagine the power and speed of the procedure as the full beams power is transmitted to the target. Reduce blown fibers, and blown blast shields plus, eliminate the need to use two or three fibers. One Fiber and Done.

The second irrefutable fact is that about 80% of all lasers in the field have drifted out of the manufacturers specifications. Gone with that are the promised expectations of the laser and the fiber. It’s no one’s fault, like low air in a car’s tires, it just happens.

If the power does not enter the transmissive core it is not delivered to the target, period. Our Lithowise fiber uses a specifically designed fiber optic thread to deliver all the energy to the target, including errant power. Avoid blown fibers, and blast shields plus, eliminate the need to use two or three fibers. One Fiber and Done.

Over 30 years of manufacturing the specialized fiber thread, and crafting the laser fiber makes Lithowise fibers the Wise choice. Choose the fiber that anticipates out of spec lasers, choose LithoWise. We build the concept of One Fiber and Done into every fiber we build. Get all of the promised power from the laser through the fiber, choose LithoWise. One fiber and Done.

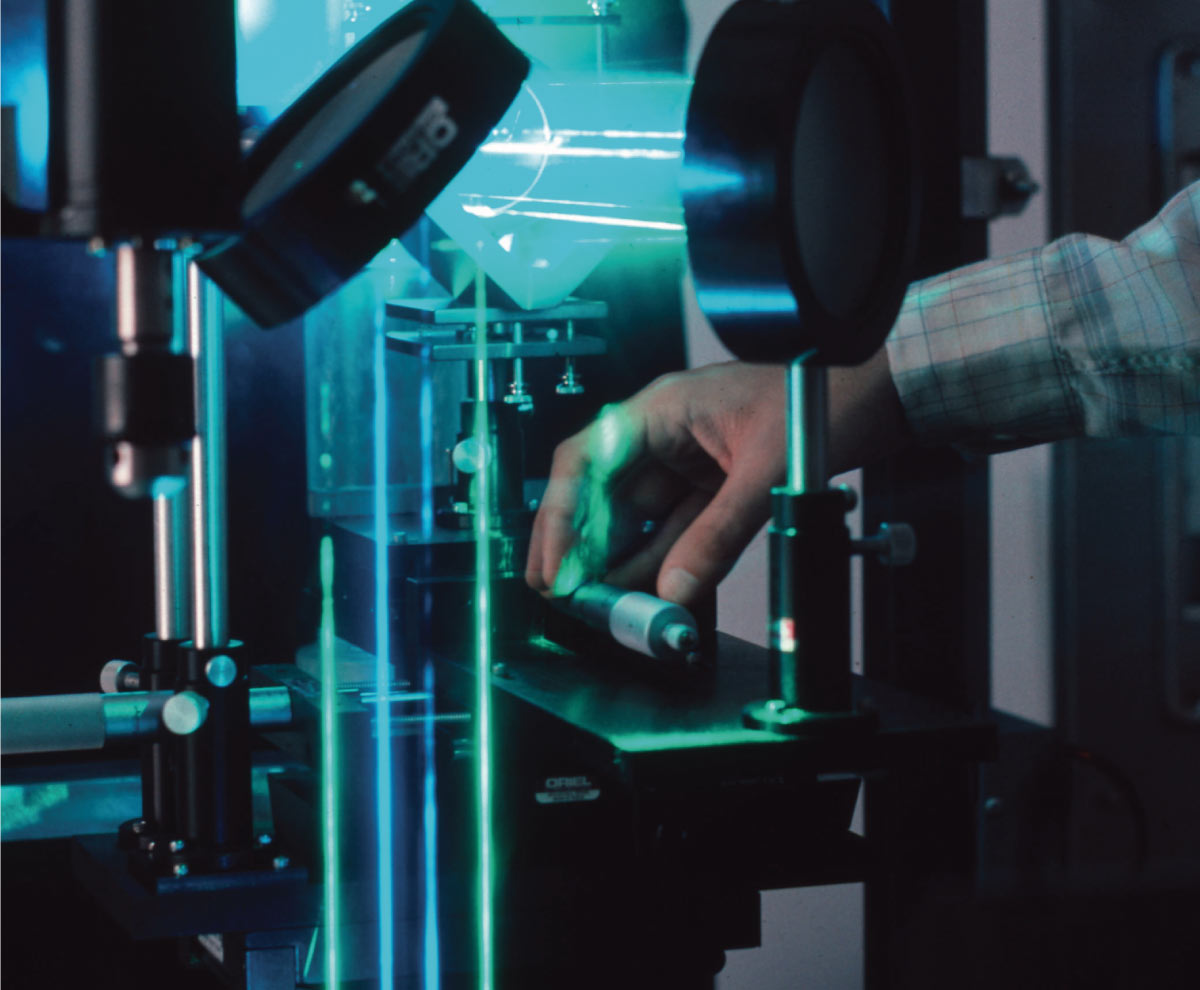

Manufacturing PROCESS

You now know that 80% of all lasers are out of spec and that our manufacturing process anticipates this fact every step along the way. While your laser is well tuned it is the exception not the rule. Our job is to manufacture a product that performs with accuracy, especially when the lasers have slowly and undetectably drifted from their design specification. We manufacture that corrective quality into the fiber thread and then into the device so that your patient experiences the best treatment using only one fiber, saving you time (up to twelve minutes) and the cost of second and third fibers. One Fiber and Done.

We start manufacturing the LithoWise Holmium Fiber by selecting the optimum optical fiber thread for the job. Using our own specially designed thread we capture every available photon of light from your laser by anticipating that it is out spec. It is centered on the beam with crosshair accuracy to the core transmission area of our fiber thread to keep the beam and power preserved, even in a tightly bent scope. We attach the fiber to a connector that is specially designed hand in hand with our specially designed fiber thread to help prevent blast shield damage over time and usage. Maximum energy is delivered per shot. One Fiber and Done.

Quality Control

We test 100% of our LithoWise fibers for throughput. We package the fiber in a tube and seal it in a Tyvek pouch. Once sterile a double look test is performed to check labels, and seals. Keep in mind, the fiber threads optical design, as well as the overall design of the device, are the keys to our great product. We test 100% for a purpose, so that you have 100% confidence in our product, its design, its manufacture, and its use on your patient. One Fiber and Done.

Testimonials

Laser repair company owner Ken

“All day long I repair and align lasers to the manufacturers factory specifications. Some of the lasers I align are terribly out of spec yet the SideWise fibers continue to work even when the laser manufacturers own fibers need two and more fibers to get the job done. I’ve been to the factory, I know how it’s made and why it is made the way it is. Well done FFI, 30 years of manufacturing and refining makes a huge difference in my business.”

Rental company owner John

“This is the only Litho fiber I use. I went to the factory and watched it being manufactured and tested. It is the best product I can buy, period. It works first time, every time and is compatible with all my lasers.”

© 2020 Copyright Fiber Optic Fabrications, Inc.

495 Main Street

Wilbraham, MA 01095

(413) 374-4301